The First Revisions

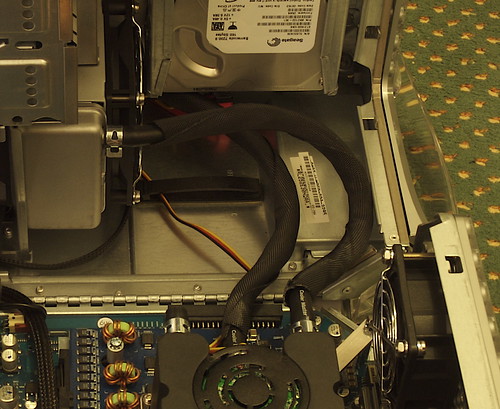

There's always a few things left over, and the first thing on my list are those rubber hoses. With a few pointy edges around the back of the case and hard drive caddy the last thing I wanted to happen was the hoses to get worn, or at worst, leak, due to abrasion when opening or closing the side of the machine. It took a fair bit of searching, but I eventually came across a company called Printasleeve in the UK who could supply me with some monofilament wraparound braid they call 'wevawrap' that could be retrofitted to the hoses.

This provides a really tough outer coating to the soft rubber pipes, although putting it on and getting the twist right so it doesn't gape open took a bit of doing. The wevawrap on the lower pipe is 9mm, while the upper one is 13mm - there's a fair bit of crossover regarding the fit, but I reckoned that a bit of extra room on the upper pipe wouldn't do any harm. They are cable-tied at either end (not yet done on this pic) and I can now open and close the case with no worries about the hoses.

Noise Annoys

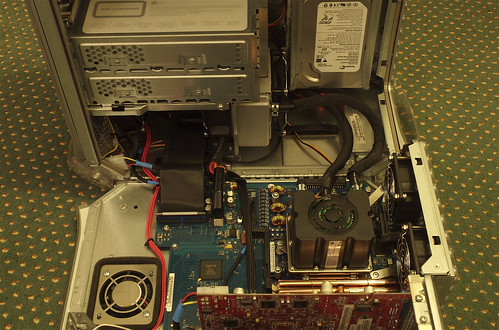

After all this work, something was whining. It was pretty loud when the temperatures got into the mid fifties, and at first I was worried that it might be the Panaflo on the back of the radiator - there's nothing else that will fit in there but an 80x15mm fan. I turned off nap mode and let things heat up, opened the case and had a listen. Then I unplugged the optical drive bay fan. I thought I'd turned off the machine.Because the optical drive fan is on the same speed controller as every other fan, it naturally speeds up with the others when the temperature rises. And because it's made by Delta, it naturally likes to let you know that it's doing something - usually by saying "phweeeee!". By dropping the values in AppleFan.kext I had inadvertently made the noise from the optical drive fan worse, so I had to find a replacement. As it happens I had bought a couple of 60x15mm fans ages ago, when I had first thought of putting some extraction on the back of the case. I honestly don't know why I never used them, but it appeared that they would be a perfect fit.

This is an Apple case. You know it's not going to be a perfect fit off the shelf. ;o) The seven-bladed Delta AFB0612HHB ran at 4500rpm at 12V, shifting 17.3 CFM @ 35dBA using 180mA. I'm replacing it with a (rather cheap) eleven-bladed AVC C6015B12L, which also runs at 4500rpm at 12V, shifts 17.2CFM, but at 27dBA using 150mA. Allegedly. I haven't seen an AVC spec sheet, but these are the general ratings I could find, and it is certainly very quiet.

If you take a peek at the picture, you should just be able to see what I had to do to the fan to make it fit. Two of the mounting holes needed to be widened to fit the posts through, and it would seem that the fan is about half a millimetre thicker than the Delta, so the plastic over the same mounting holes had to be filed to give that gnat's crotchet of extra space, otherwise the metal plate just won't go back in position. Is it perfect? Almost. The starting voltage of the fan must be dead on 5V, because the first couple of starts it just didn't get moving. In fact, as I've been using the machine, it seems to be about 50/50 as to whether it gets going on startup or not. It never stalls once it's running, but I'll need to keep an eye on this, because stalled / stuck fans can draw much more current than when they are running, and potentially burning out tracks on my logic board is not my idea of fun.

Tidy Up Time

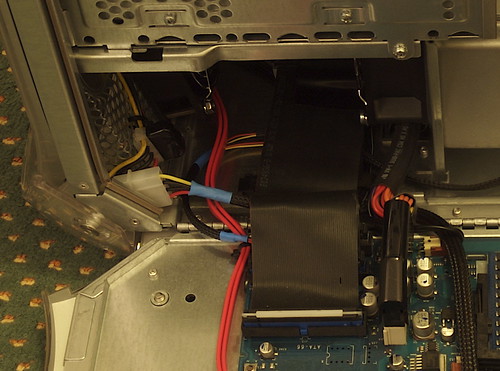

Last on the list was just a quick bit of braiding for the front grille and rear radiator fan. The blue heatshrink arrived and everything's looking well-wrapped and secure. You can see on the shot above the additional IDE cable I've left on the logic board, just in case I need it.

Job done!

Specifications and The End >>